IQC Brake Test System

Tailored to your requirements our Brake Rotor / Drum Test System detects faults based on user-defined metrics – with statistically generated tolerance limits.

Today’s brake system suppliers are faced with quality requirements that far exceed identifying manufacturing defects. Vehicle OEMs are now calling for the inspection and conformance to resonance frequencies along with the identification of specific mode shapes – such as nodal diameters, infriction, and hat modes.

Ensuring that such critical and specifications are met requires a sophisticated and objective test system. Unfortunately, many brake rotor and brake drum manufacturers continue to rely on machine integration or home-grown solutions for their quality inspectors.

The key is to implement objective test and analysis solutions born from the same Modal Analysis Theory that the OEMs use to design the performance criteria written into their print specifications.

Brake Rotor & Drum Test System

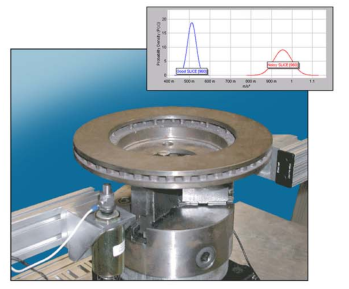

Tailored to your requirements, the Signalysis Brake Rotor and Brake Drum Test System replaces subjective tests with advanced frequency inspection metrics. Designed to operate manually as an audit solution in your quality lab or integrated as an online 100% production line, this proven test system combines traditional NVH laboratory spectral and modal analysis methods delivering 100% inspection confidence to your manufacturing floor.

The Signalysis Brake Rotor/Drum Test System replaces subjective tests with advanced frequency inspection metrics. The system is designed to operate manually or integrate into your production line. This proven test system combines traditional NVH laboratory spectral and modal analysis methods delivering 100% inspection confidence to your manufacturing floor. Test results can be passed to on-line statistical control systems.

- Analysis results are compared against your specifications and quality requirements to provide a Go/No Go signal

- Identifies Resonance Frequency and damping characteristics

- Controls the part in place and provides the required vibration isolation from the manufacturing facility

- Generates the modal excitation, measures force and response of the rotor to calculate FRF

Contain Customer Complaints

- 100% Inspection of all Brake Rotors/Drums

- Maintain Tolerance on Resonance Frequency of Brake Drums &

Rotors - Maintain Tolerance on Separation of Critical Modes of Vibration

- Maintain Damping

- Meet Customer Cycle-Time Demands

- Provide Daily Production Reports

- Other Objectionable Noises

Analysis

- Frequency Response Function

- Resonance Frequencies

- % Critical Damping

- Q Factor

- Spacing Modes

Measurements

- Excitation Force: Impact Force & Band Limited Random

- Vibration Response: Acceleration, Sound Pressure & Velocity W/Laser Vibrometer

- Dimensional Parameters

- Vision Inputs

- High Frequency Inspection

Powered By

Contact Us

Call 513-528-6164 or use the form below