Product LifeCycle Quality

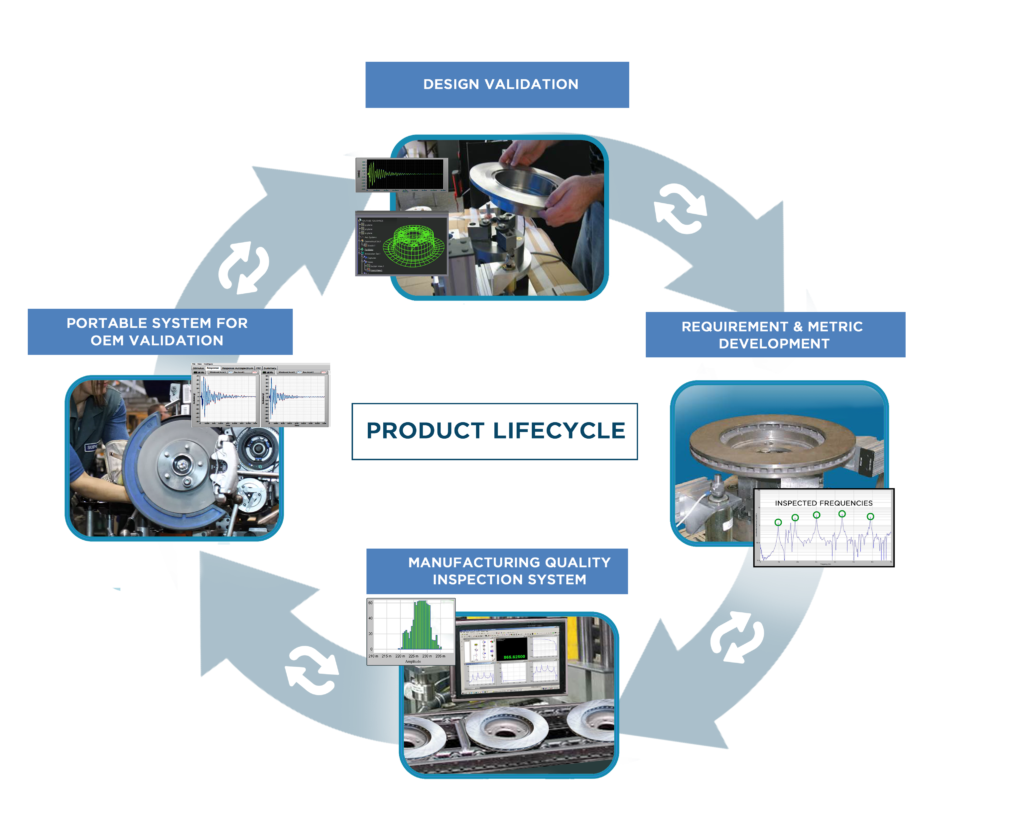

When it comes to quality, there’s no room for subjectivity, guesswork or trial by error engineering. Implementing Signalysis early upstream and throughout the product life cycle saves time, money and improves quality. The data flow from Design Validation testing lead to better Requirements and Metric Development which accelerates and improves the Production Quality Inspection process and can roll out to OEM and Field Inspection Testing. All of this leads to improved quality and greater confidence in current and next generation products.

Signalysis ensures that quality requirements are met throughout the entire product lifecycle

End-to-End Product Quality Assurance

Design Validation

The Signalysis Design Validation platform helps ensure product design integrity in the early upstream stages and throughout the product lifecycle. Our range of product design validation solutions include Acoustic & Modal Testing, Functional Testing, Data Analysis, Durability testing, and Early Warning Detection designed help you anticipate and avoid potentially catastrophic failure.

Requirements & Metric Development

Validating the design provides engineering with the data to identify meaningful requirements and create specific metrics to qualify the manufacturing process. Signalysis provides a means to: Test Performance Specifications, Define Test Requirements, Set Critical Fixture Requirements and Define Quality Metrics.

Manufacturing Quality Inspection Systems

Eliminating subjectivity ensures that product quality standards are consistently met. Test requirements and metrics that evolve from validation are used to develop objective quality inspection tests. This can be a combination of 100% online for sub-assemblies and audit tests. Following this process from start to finish allows companies to put hard and fast requirements on suppliers’ quality inspection systems. Designed for your specific requirements, Signalysis End-of-Production Quality Inspection solutions capture defects before products reach the customer while providing the ability to report costly production issues for redesign.

Remote Troubleshooting

Products in the customers’ hands can be subjected to unanticipated usage and operating environments. The Signalysis In-Field Test System allows real-world operating data to be captured and analyzed in the product’s usage environment. Comparing this information to that used to validate the initial design provides valuable design and usage insight. Sharing test results with design helps ensure that redesigns and next generation products will meet expectations.