Medical Equipment Testing

Noise and vibration of medical devices play a huge part in patient annoyance, patient safety and surgeon comfort. Consider the case where noise caused by defective gears or bearings scare a patient into moving during x-ray scanning. The result is a second dose of radiation just to get the right picture.

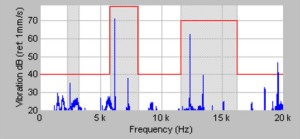

The IQC Production Test System is designed to perform 100% inspection of medical devices for vibration and noise defects. The system replaces subjective tests with an arsenal of signature analysis algorithms designed to objectively identify issues at early stages in the production line.

The IQC Noise testing can identify beeper that is out of tune, a speaker that distorts important instructions or even a required sequence of verbal instructions that has been programmed incorrectly into a device. Vibration may come into play with imbalanced dental tools or defect in miniature air turbines that hand-held tools resulting in substandard performance.

For more than 30 years Signalysis has been a technology innovator of test measurement for end-of-production testing.

Medical applications include:

- The Study of Biomechanics Associated with Sports Flooring

- Hand & Arm Vibration of Dental Tools & Surgical Cutting Devices

- Noise Testing on Speaker & Enunciators Embedded in Instruments

- Performance Testing on Air-Driven Devices

- Noise Detection of Air Compressors

- Bearing & Motor