Ensuring Brake Pad Quality

Signalysis’ Robert Cagle has authored and presented papers on brake pad quality testing. Watch this short video to learn more about Signalysis brake pad quality inspection solutions.

Quality Inspection Test Systems

Generally traced to manufacturing quality issues, brake pad defects can include cracks in the friction material, friction material not properly bonded with the metal backing, chips, and more. Signalysis Brake Pad Quality Inspection Test Systems replace subjective quality inspection with objective, science-based quality testing.

Our test systems are providing a growing number of suppliers with confidence that the parts they ship meet the highest quality standards.

With 100% quality inspection, Signalysis brake pad test systems:

- Maintain the highest quality standards

- Eliminate interpretation and bias

- Provide confidence

- Provide reliability and consistency

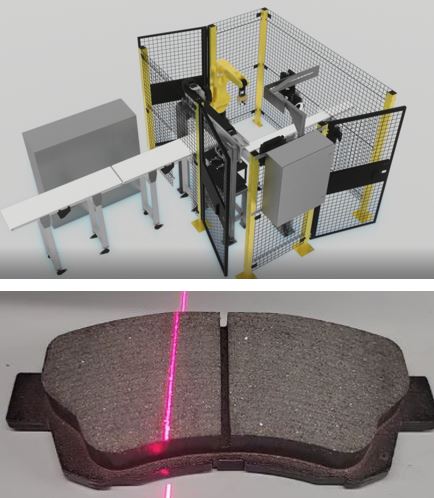

Visual Inspection Brake Pad Test System

While frequency inspections address many of the critical and safety related defects there are instances when other methods are required to manage a 100% unmanned and objective inspection.

Signalysis Visual or Laser Profiling Inspection Test System identifies abnormalities such as material buildup, small chips, scratches, missing clips, damaged shim defects, etc. This also include presence and reading of codes and lot numbers.

Powered By

Contact Us

Call 513-528-6164 or use the form below