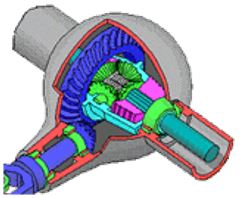

Real Wheel Drive Transmission

Contracts for Tier 1 automotive suppliers are only as good as the quality of their products. And for this Tier 1 rear axle assemblies’ supplier, winning a contract for a luxury vehicle would hinge on the implementation of a production line test system to quantitatively assess final drive transmission errors.

Contracts for Tier 1 automotive suppliers are only as good as the quality of their products. And for this Tier 1 rear axle assemblies’ supplier, winning a contract for a luxury vehicle would hinge on the implementation of a production line test system to quantitatively assess final drive transmission errors.

So naturally, with a contract on the line, Signalysis was called in to help.

Solution: Quality Inspection Test System

An Signalysis Production Line Test System was integrated with a third-party test station to conduct 100%-part inspection. The system acquired and processed running data, assessed pass/fail, and archived the pertinent data.

The inspection station was installed at the earliest point possible in the assembly line to identify “bad” gear sets prior to full axle build. All tests were performed at a constant speed with several torque conditions including Drive Torque, Coast Torque, Torque Sweep, and Coast to Drive.

The system confirms the test cell achieved correct speed and quasi-static running torque and calculates dynamic torque amplitude at mesh frequency for each steady state torque condition.

In addition, the Signalysis system:

- Calculates peak torque value at mesh frequency for torque sweep

- Compares torque amplitude to established limits to assess pass- fail limits

- Exports metric values to central manufacturing database for SPC activities

- Automatically processes data from different models (i.e., F/D ratios)