Non-Destructive Testing

Non-Destructive testing (NDT) is a process to evaluate/inspect the properties of raw or machined parts without causing damage. Signalysis NDT experience and solutions include Resonance Frequency Inspection, Eddy Current, and Ultrasonic.

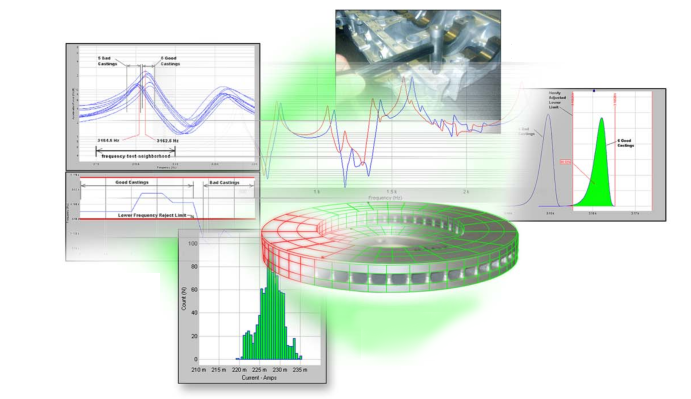

The Dinger

The Dinger, Signalysis’ non-destructive test solution, provides PASS/FAIL parts testing.

- Resonance Frequency Inspection

- Damping and Q-Factor

- Locate Surface and Subsurface Flaws

- Fast Crack Detection in Powdered Metal Parts

- Quick Detection of Gray vs Ductile Iron

- Nodularity Inspection Without the Destruction

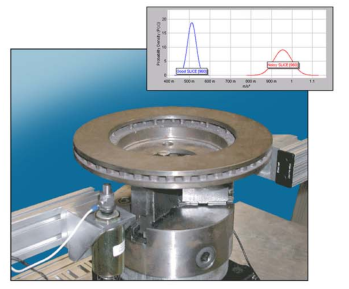

Brake Rotor Test System

Our Brake Rotor/Drum Test System operates manually or integrate into your production line. This proven test system combines traditional NVH laboratory spectral and modal analysis methods delivering 100% inspection confidence to your manufacturing floor.

- Analysis results are compared against your specifications and quality requirements to provide a Go/No Go signal

- Identifies Resonance Frequency and damping characteristics

- Controls the part in place and provides the required vibration isolation from the manufacturing facility

- Generates the modal excitation, measures force and response of the rotor to calculate FRF