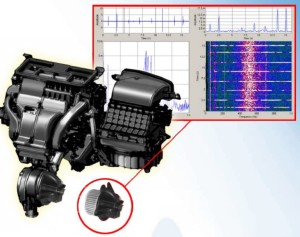

IQC HVAC Production Test Systems

Tailored to your requirements our automotive HVAC test system detects faults based on user-defined metrics — with statistically generated tolerance limits.

Based on more than 30 years of experience, the Signalysis HVAC Production Test System replaces  subjective tests with advanced vibration, sound, motor current and actuator performance metrics. Combining traditional NVH laboratory modal analysis, sound quality, gear testing, and motor dynamics test methods this proven test system brings 100% inspection confidence to your manufacturing floor.

subjective tests with advanced vibration, sound, motor current and actuator performance metrics. Combining traditional NVH laboratory modal analysis, sound quality, gear testing, and motor dynamics test methods this proven test system brings 100% inspection confidence to your manufacturing floor.

IQC AUTOMATION

Controls HVAC operation through a defined list of functional tests. This maximizes test cycle time and optimize test data integrity.

IQC MEASUREMENT SYSTEM

Acquires dynamic response data from a defined set of transducers, sampling rates, digital filters, and sample sizes.

IQC ANALYSIS ENGINE

Employs high-level post-processing in time and frequency domains to detect faults in drive motors, gear systems, and other mechanical or moving parts during HVAC operation.

CONTAIN CUSTOMER COMPLAINTS

- MOTOR IMBALANCE

- FAN BLADE PASS

- ACTUATOR CLICK / TICK

- SLOW ACTUATOR

- ACTUATOR ANGLE OF ROTATION

- OVERALL VIBRATION

- BEARING NICKS

- OVERALL DB(A)

- OTHER OBJECTIONABLE NOISES

AUTOMOTIVE ANALYSIS

- FOURIER TRANSFORMS

- HILBERT TRANSFORMS

- ORDER ANALYSIS

- RMS

- SPL DB(A)

- MAX MOTOR CURRENT

- MOTOR CURRENT FLUCTUATION

- PULSE COUNTING

- DUTY CYCLE

VEHICLE MEASUREMENTS

- DYNAMIC MOTOR CURRENT

- STATIC MOTOR CURRENT

- VIBRATION – ACCELERATION

- ACTUATOR MOTION – ENCODER

- SOUND PRESSURE – MICROPHONE

- MOTOR SPEED

- TIME DOMAIN

- FREQUENCY DOMAIN